Product Overview

NOTE: Shipping Rate not available in Hawaii, Alaska or Puerto Rico.

DTRON 2

Description:

Option 1: Includes pump only.

Option 2: Includes Pump Base with 1" threaded side inlet connection for 1" Floating Filter to connect with a 6' Hose

Option 3: Includes Pump Base with 1" threaded side inlet connection for 1 1/4" Floating Filter to connect with a 6' Hose

Option 4: Includes Pump Base with 1" threaded side inlet connection and required Adapters for 1 1/2" Floating Filter to connect with a 6' Hose

Option 5: Includes Pump Base (DOC68) with 1 1/4" threaded side inlet connection and required Adapters for 2" Floating Filter to connect with a 6' Hose

DTron 2 is a 7” submersible electronic multi-impellers pump for clean water designed for use in wells and tanks. It can be used submerged, partially submerged or on the surface (with the appropriate accessory). It is suitable for use in domestic and residential environments for pressurization, rainwater reuse, gardening and irrigation activities. The pump can be installed even horizontally. It is also available in version X with 1” inlet and kit X which includes 6 ft suction hose and float to prevent the suction of impurities from the bottom. The entire pump is classified IP 68, with the DOC68 accessory (supplied separately) it becomes an IP 68 surface pump that can be used under the level of the water. On request a certified version for drinking water is available. The expansion vessel is integrated, no external expansion vessel is required.

TECHNICAL DATA

1.25" Female Threaded Outlet

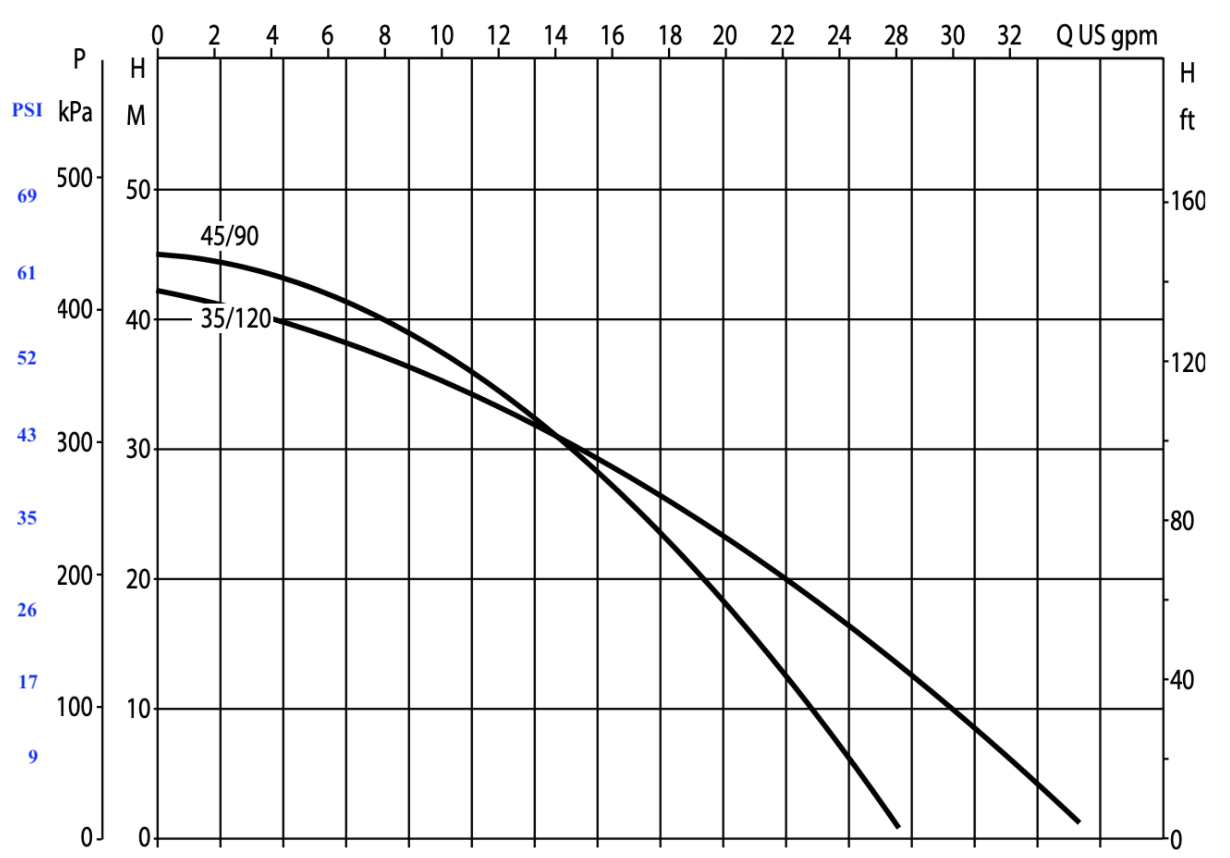

Flow rate maximum: 32.1 GPM (7.3 m3/h)

Head up to: 147 ft (45 m)

Maximum immersion depth: 49 ft (15 m)

Type of pumped liquid: Clean, free from solid or abrasive substances, non-viscous, non-aggressive, non-crystallized and chemically neutral

CONSTRUCTION FEATURES OF THE PUMP

Technopolymer pump body to resist corrosion and oxidation. Integrated check valve. Integrated debris filter. Overpressure valve to resist to the formation

of ice in the piping and to protect from water hammer. On the pump body there is a air-vent valve that improves priming during the first installation or

in the event of emptying the tank/well. Technopolymer handle to move the pump. Integrated 0,04 liter expansion vessel sized to prevent the pump from

cycling in the event of small leakages and to compensate in case of water hammer. No maintenance or recharging is required for the integrated vessel.

The coupling between the three impellers in technopolymer, the floating ring and the smoothing disc both in stainless steel allow a limited wear of the

hydraulics. Suction height can be adjusted using the appropriate accessory (included): 1.4” - 1.6” - 2.4’ or 3.2“ (3.5 - 4 - 6 or 8 cm).

CONSTRUCTION FEATURES OF THE MOTOR

Asynchronous submersible water cooling motor. The hydraulic side of the motor shaft is in AISI 303 stainless steel. Double mechanical seal in oil

chamber ensure the pump watertight. Capacitor and integrated anti-overheating motor for thermal protection. Quick coupling/release cable to facilitate

installation inside tanks. Anti tear-off power cable connection.

FEATURES OF THE ELECTRONIC

The electronic operation allows the pump to start and stop autonomously by the system requirements and protects against the dry run. NFC (Near Field

Communication) pocket for the use of a floater sensor (supplied separately) which can be connected without opening the pump and so maintaining a

watertight seal. The ANTI-FLOOD protection intervenes in the event of a malfunction of the shutter. The ANTI-BURPING protection protects the pump from

false starts in the event of gurgling water.

Documentation