Product Overview

Grundfos has discontinued the PM1 and PM2 Pressure Manager and replaced it with the new PM Plus. See the CM Booster Plus 3-5.

NOTE: $35 Fixed Shipping Rate not available in Hawaii or Alaska.

With a CM Booster 3-5 On Demand Pump, you can expect much higher flows and pressures than that of the popular MQ 3-45 model but with the same on demand functionality. The CM Booster Pumps are made with higher quality components (all stainless steel internal parts) and have a significantly longer life expectancy than that of the MQ 3-45. The CM Booster combines the Grundfos CM 3-5 Pump with the Grundfos PM2 Pressure Manager, making it a high quality, high performance above ground pump with on demand capabilities.

The Grundfos CM Booster Self-Priming is a compact booster pump designed for domestic and light industrial use. The booster unit consists of a robust multistage centrifugal pump and a generator friendly PM2 Pressure Manager.The Pressure Manager allows the pump to start and stop automatically according to demand and protects the pump from dry running. The CM Booster Self-Priming is the perfect solution if you are struggling with insufficient mains pressure, and it can also be used with above or below groundwater sources.

Applications

- Mains water pressure boosting

- Rainwater supply from above ground water tanks

- Rainwater supply from below ground water tanks

- Rainwater supply from other below ground water sources - dams/rivers etc.

Features

- 1.5HP

- Compact (small footprint)

- Easy installation

- High reliability

- Wide performance range

- Automatic resetting of alarms

- Adjustable pressure settings

- Dry-running protection

- Anti cycling (leak detection)

- Max continuous operating time

- 110V (3-prong plug plugs into 110 wall outlet)

Pump

- Low noise level

- Grundfos motor

Pressure Manager

- User-friendly interface

- Flexible power supply

- Internal pressure tank

- Power-on indication

- Pump running indication

- Alarm indication

- Dry-running protection

- 1" FNPT outlet connection

Documentation:

CM Brochure

CM Product Guide

CM Installation and Operating Instructions

PM2 Brochure

PM2 Product Guide

PM2 Replacement Chart

Submittal Document

Performance

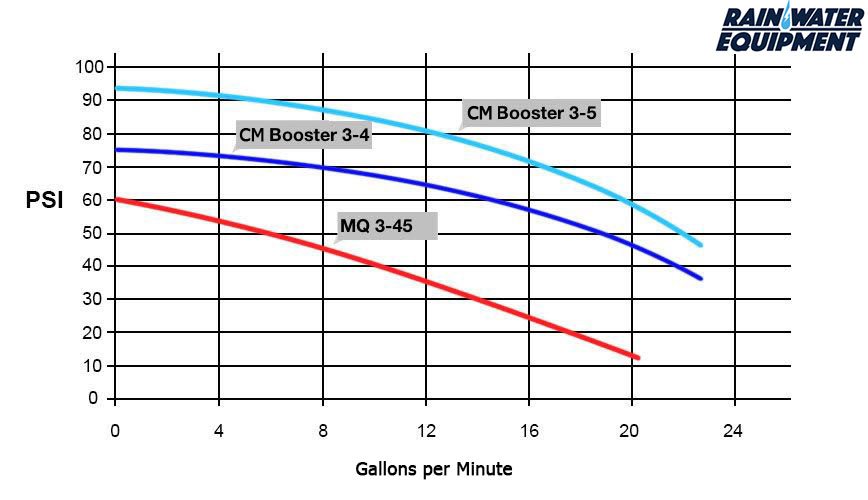

Compares flow and pressure of the CM Booster to the popular Grundfos MQ 3-45 pump. The CM Booster 3-5 pump offers higher and flows and pressures with the same on demand functionality. It will supply 12 GPM (Gallons per minute) @ 80 PSI, 16 GPM @ 70 PSI and 20 GPM @ 60 PSI at the pump's discharge. The CM Booster 3-5 is made with higher quality components (all stainless steel internal parts) and has a significantly longer life expectancy than that of the MQ 3-45.

About the CM 3-5

The Grundfos CM pump has been created with compactness, flexibility and reliability as its central features. This horizontal multi-stage, close-coupled pump is a compact, reliable and quiet pump designed to work in a variety of applications.

CM pumps are fitted with mains-operated motors.

A Grundfos engineered mechanical shaft seal has been designed to eliminate industry-wide problems with shaft seals sticking where SIC-SIC seal faces are used. The solution builds on both the implementation of a rotation stop on the stationary ring and different surface finishing on both the stationary and rotating rings.

Flexibility

The Grundfos CM is designed to be used in a variety of applications, including:

- Washing and cleaning (washing machines)

- Rainwater Harvesting (flooded suction from a water storage tank)

- Temperature control (heating/cooling)

- Building services

- Irrigation

| Feature | CM Booster Self-Priming |

|---|---|

| Pressure Manger 2 (refer to table below | Yes |

| Self-Priming capabilities | Yes |

| Stainless steel wetted components | Yes |

| Feature |

Pressure |

|---|---|

| Power on indication | Yes |

| Pump running indication | Yes |

| Alarm indication | Yes |

| Dry-running protection | Yes |

| Free position in installation | Yes |

| Suitable for generator supply | Yes |

| Rotary outlet connection | Yes |

| Integrated non-return valve | Yes |

| Cycling alarm | Yes |

| Integrated pressure sensor from Grundfos Direct Sensors | Yes |

| Adjustable start pressure | Yes |

| Start/stop with 1 bar differential pressure | Yes |

| Auto restart after dry running | Yes |

| Maximum run time 30 min (safety) | Yes |

| Pressure indication | Yes |

| Internal pressure tank | Yes |

Features and Benefits

Robust design

All wetted parts are made from high quality, corrosion resistant stainless steel to ensure the longest life possible.

User-friendly interface

The pump features a user-friendly interface with LED indicators displaying power status, pump running, alarm indication and pressure indication.

Protective features

The pump incorporates a range of protective features such as; dry run protection, thermal overload protection, cycling alarm and maximum continuous operation time - 30 mins to protect the pump and ensure a long life.

Easy installation

The booster unit is a compact and adaptable solution, which makes it suitable for most installations. Simply connect the inlet and outlet and adjust the start pressure to suit individual requirements and you have a fully operational booster unit.

Integrated non-return valve

Non-return valve for backflow prevention.

About the PM2

The PM2 Pressure Manager is a controller that allows your pump to operate "on demand". On demand essentially means that when there is a drop in pressure in the water line, the PM2 will send a signal to the pump to turn on and begin pushing water. The pressure drops until it reaches 20 PSI to 32 PSI (1.5 or 2.2 bar), then starts the pump. The pump will continue to run until the demand for water stops. E.g. A valve is closed, and the flow of water ends. At this point, the PM2 will send a signal to turn off the pump.

The Grundfos PM 2 pressure manager is designed for automatic start/stop control of Grundfos pumps and other water supply pumps. The PM 2 is the all-round control solution offering adjustable start from 0-90 PSI. This enables customization to different types of installations at the desired comfort level. The start pressure is set by means of DIP switches located behind the control panel, whereas the current pressure is indicated on the LED display on the front of the PM 2. The PM 2 starts the pump when the start pressure is reached, and the pump keeps running as long as there is a flow. The PM 2 can be optimized for operation with an external pressure tank by enabling the 14 PSI differential-pressure function. This function significantly reduces the number of operating hours of the pump in installations with pressure tank.

Furthermore the PM 2 incorporate a number of functions which protect both the pump and the installation.

Protective functions include:

- dry-running protection

- cycling alarm

- maximum continuous operating time (30 minutes)

- auto-reset function which can be used to automatically restart the pump

Power: 110V

PM2 Features/Dip Switch - Quick Reference

Inside the cover of the the PM2 are 8 dip switches. Below is a quick reference of what these switches are designed to do, but be sure to consult the Grundfos' Quick Start Guide and Product Guide for more comprehensive details/instructions.

Dip Switch #1 - Flipped up increases the set point pressure in which the pump will start by 7 PSI or 0.5 bar (Factory set at 20 PSI or 1.5 bar) So, the pump will kick on at approx. 27 PSI

Dip Switch #1 and #2 - Flipped up increases the set point pressure in which the pump will start by an additional 15 PSI or 1.5 bar. So, the pump will kick on at at approx. 40 PSI.

The pump will turn off when it senses that there is no water flowing through the unit.

NOTE: There won’t be an instance when you need to use Dip Switch #3 or #4 with a CM Booster Pump 3-4 or CM Booster 3-5 because these on demand pumps don’t generate enough pressure to warrant enabling them.

Dip Switch #1, #2 and #3 - Flipped up increases the set point pressure in which the pump will start by an additional 15 PSI or 1.5 bar. So, the pump will kick on at at approx. 65 PSI.

Dip Switch #1, #2, #3 and #4 - Flipped up increases the set point pressure in which the pump will start by an additional 15 PSI or 1.5 bar. So, the pump will kick on at approx. 80 PSI.

Dip Switch #5 - Flipped up sets a 15 PSI deactivation point (rather than allowing lack of water flow to stop the pump). This should only be used with pumps that produce very high pressure (like 150 PSI, for example). Sets a max 15 PSI differential between On/Off points.

Dip Switch #6 - Flipped up turns on the Auto Reset feature which automatically resets the pump when it enters into an alarm mode such as dry run protection. This will allow the pump to resume operation when water/flow returns and the pump is able to reprime the suction line. When the auto-reset function is enabled, cycling and dry-running alarms will be automatically reset. When the auto-reset function is enabled, the pump will be restarted automatically after 12 hours in alarm condition. Note: The auto-reset function should NOT be enabled on pumps which cannot self-prime when water returns after dry-running. The CM series pumps (Including the CM 3-4 and CM 3-5) are NOT self priming.

If Auto-reset is not turned on, the PM2 can be manually reset by pressing the reset button.

Dip Switch #7 - Flipped up activates the Anti-cycling feature. If the pump starts and stops 5 times consecutively, it will go into alarm if #7 is flipped up.

Dip Switch #8 - Flipped up activates 30 Minute Max Operating Time. When the function is enabled, any water usage exceeding 30 minutes will cause an alarm, and the pump will be stopped. If enabled, the auto-reset function will not restart the pump.

Alarm Conditions – There are 3

1) Top Solid Red Light indicates Dry Running

2) Blinking Red Light indicates that the pump has been cycling and has stopped due to the anti-cycling feature. Dip Switch #7 must be flipped up for this alarm to occur.

3) 2 Fast Blinking Red Lights (followed by a pause) indicates that the pump has run for 30 minutes continuously and has shut off because it assumes there is either a leak in the pipe, broken pipe, faulty diaphragm inside a pressure tank being used, or water has been left running. Dip Switch #8 must be flipped up for this alarm to occur.

The pump will only go into alarm in these scenarios if the feature (corresponding dip switch) is enabled.

PM2 has an integrated diaphragm and can be used without a larger pressure tank, but a pressure tank will reduce the number of times the pump starts/stops.